Packaging plays a critical role in preserving the quality and safety of products, particularly in industries like beverages, pharmaceuticals, cosmetics, and more. One essential element of effective packaging is the proper sealing of bottles. A secure seal not only prevents leakage but also ensures product freshness and safety. The Bottle Cap Torque Tester is an indispensable tool for manufacturers aiming to maintain optimal packaging quality.

What is a Bottle Cap Torque Tester?

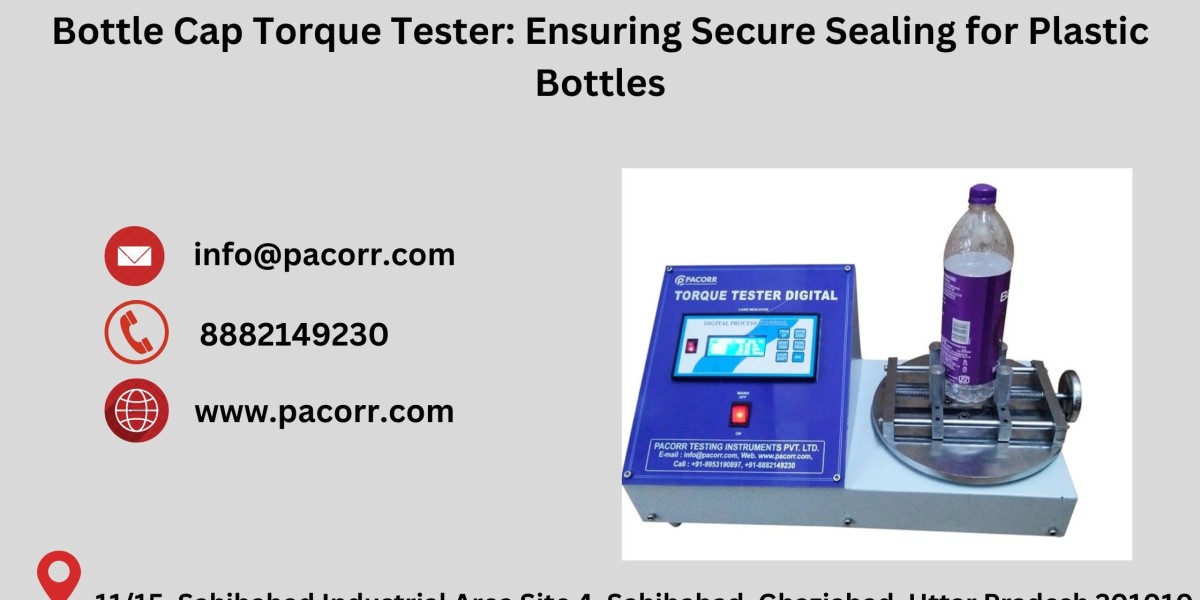

The Bottle Cap Torque Tester is a precision instrument designed to measure the torque strength of bottle caps. It helps manufacturers ensure that caps are neither too tight to cause inconvenience to users nor too loose to compromise the seal. By evaluating the application and removal torque of caps, this device plays a crucial role in quality control processes.

Features of the Bottle Cap Torque Tester

- High Precision: Offers accurate torque measurement to ensure compliance with industry standards.

- Digital Display: Provides easy-to-read results, improving efficiency and reducing errors.

- User-Friendly Interface: Simplifies the testing process with intuitive controls.

- Versatility: Suitable for different bottle sizes and cap designs.

- Durability: Built with robust materials to withstand industrial usage.

Importance of Torque Testing

Proper torque testing is vital to maintaining packaging integrity and avoiding costly issues like product recalls. Here are some key benefits:

- Ensures Consumer Safety: Prevents product leakage and contamination.

- Improves Brand Reputation: Ensures consistent quality across all products.

- Compliance with Standards: Meets regulatory requirements for packaging.

- Reduces Waste: Optimizes the capping process to prevent over-tightening or under-tightening.

Applications of the Bottle Cap Torque Tester

This device is widely used in:

- Food and Beverage Industry: Ensures airtight seals for juices, soft drinks, and sauces.

- Pharmaceutical Sector: Verifies tamper-proof seals for medications.

- Cosmetic Industry: Confirms secure seals for lotions, creams, and perfumes.

- Chemical Industry: Validates safe sealing for chemicals and solvents.

How to Use the Bottle Cap Torque Tester

- Place the bottle securely on the tester’s platform.

- Adjust the fixture to hold the bottle firmly.

- Select the testing mode (application torque or removal torque).

- Rotate the cap manually or automatically as per the tester’s configuration.

- Record the torque reading displayed on the screen.

Choosing the Right Bottle Cap Torque Tester

When selecting a torque tester, consider factors such as:

- Range of Measurement: Ensure it covers the torque range required for your applications.

- Bottle Compatibility: Verify the tester’s ability to handle different bottle sizes and shapes.

- Accuracy and Calibration: Opt for a device with high precision and easy calibration features.

- Durability: Choose a robust model designed for industrial use.

Conclusion

The Bottle Cap Torque Tester Price is a must-have instrument for manufacturers striving to deliver quality and safety in their products. With its ability to ensure perfect sealing, this device not only enhances product integrity but also boosts customer trust. Investing in a reliable torque tester is a step toward achieving excellence in packaging.

FAQs: Bottle Cap Torque Tester

1. What is the purpose of a Bottle Cap Torque Tester?

The Bottle Cap Torque Tester is used to measure the application and removal torque of bottle caps, ensuring that they are sealed securely and meet quality standards.

2. Why is torque testing important for packaging?

Torque testing ensures that bottle caps are not over-tightened or under-tightened, preventing leakage, contamination, and customer dissatisfaction.

3. What industries benefit from using a Bottle Cap Torque Tester?

Industries such as food and beverage, pharmaceuticals, cosmetics, and chemicals use this device to maintain packaging quality and safety.

4. Can the Bottle Cap Torque Tester handle different bottle sizes?

Yes, most torque testers are designed to accommodate a wide range of bottle sizes and cap shapes, making them versatile for various applications.

5. How does a Bottle Cap Torque Tester improve product quality?

By ensuring proper sealing, it prevents leakage, preserves freshness, and enhances the overall consumer experience.

6. Is the Bottle Cap Torque Tester easy to use?

Yes, modern torque testers come with user-friendly interfaces and digital displays for quick and accurate readings.

7. What is the typical torque range measured by this device?

The torque range depends on the model but usually covers a wide spectrum suitable for most bottle caps in the market.

8. How often should the Bottle Cap Torque Tester be calibrated?

It should be calibrated periodically, depending on usage frequency and manufacturer recommendations, to ensure accurate readings.

9. Can the torque tester detect tamper-proof seals?

Yes, it can test the strength of tamper-proof seals to verify their integrity and compliance with safety standards.

10. Does Pacorr offer after-sales support for their Bottle Cap Torque Tester?

Yes, Pacorr provides comprehensive after-sales support, including installation assistance, training, and maintenance services.